Apple did something nobody thought possible. They started 3D-printing millions of Apple Watch cases using 100% recycled titanium while cutting material waste in half. Every Apple Watch Ultra 3 and titanium Series 11 now gets made this way.

This isn't a small upgrade. It completely changes how your Apple Watch gets made and what accessories work with it. Here's why this matters for your next watch purchase and the accessories you'll want to pair with it.

How Apple's new manufacturing process works

Apple uses something called Laser Powder Bed Fusion. Think of it like a super precise 3D printer, but way more complex:

- They start with recycled titanium powder (each grain is exactly 50 microns wide - about the size of fine sand)

- Six lasers work together to melt and shape the powder layer by layer

- This happens 900 times until your watch case forms

- Leftover powder gets recycled for the next batch

The whole process uses half the titanium compared to old methods where they carved cases from solid blocks of metal. Apple saved over 400 metric tons of titanium in 2025 alone.

Why recycled titanium was impossible before

Using recycled titanium powder for millions of watches created huge problems. Titanium powder becomes explosive when heated by lasers. Apple solved this by transforming recycled titanium scrap into a safer grade with lower oxygen content, then letting the printing process naturally strengthen it back to aerospace-grade quality.

Nobody figured out how to do this at scale until now.

What this means for your Apple Watch experience

Your new Apple Watch gets two major improvements:

Perfect consistency

Every single watch case has identical dimensions. Traditional manufacturing always had tiny variations between watches. 3D printing eliminates these differences completely.

Lighter but stronger

Your watch weighs less while keeping the same durability. The polished mirror finish on Series 11 stays perfect, and Ultra 3 maintains its rugged build quality.

How this changes accessories forever

The precision manufacturing creates opportunities that didn't exist before:

- Perfect fit guarantee: Bands, cases, and screen protectors will fit exactly right every time

- New accessory types: Lighter watches allow for premium metal bands without making your wrist feel heavy

- Better integration: Charging docks and health accessories align perfectly with internal components

- Tighter tolerances: More intricate designs become possible

What iPulse customers should expect

This manufacturing breakthrough gives you real benefits:

No more "might not fit" warnings

Since every watch has identical dimensions, accessories work perfectly across all units. You won't see compatibility disclaimers anymore.

New product categories opening up

Lighter watches enable accessories that weren't practical before:

- Ultra-thin protective cases that don't add bulk

- Premium metal bands you'll want to wear all day

- Activity-specific mounts for cycling or diving

- Advanced health monitoring add-ons

Future-ready designs

As Apple applies this technology to more products (rumors suggest iPhone Air might be next), accessories will work across multiple device generations.

Environmental impact you care about

The numbers speak for themselves:

- 50% less titanium waste

- 100% recycled materials

- 400+ metric tons of raw titanium saved in one year

Apple moves closer to their 2030 carbon neutral goal while making better products.

Frequently asked questions

Do 3d-printed cases feel different than traditional ones?

No. The final product uses the same grade 5 titanium as before. You get the same durability and finish quality, just with less weight.

Will my current accessories still work?

Yes, if you have compatible Apple Watch models. The 3D printing affects manufacturing precision, not the overall design dimensions.

Why does oxygen content matter in titanium powder?

Lower oxygen prevents the powder from becoming explosive when heated by lasers. Apple transforms recycled titanium to reduce oxygen, then the printing process naturally increases it back to the right strength.

How much lighter are these new watches?

Apple hasn't released exact weight differences, but using 50% less material while maintaining the same size means noticeable weight reduction.

Will other Apple products use this technology?

Reports suggest Apple plans to expand this to other devices. The iPhone Air model might use similar titanium 3D printing.

Does this affect battery life or performance?

No. The manufacturing method doesn't change internal components or functionality. You get the same performance with better build quality.

Looking ahead

Apple sets a new standard for precision manufacturing. For you, this means accessories become integral parts of your Apple Watch experience instead of afterthoughts.

The era of "close enough" fit is over. Every accessory gets engineered to work perfectly with your watch, opening possibilities for designs that enhance what your Apple Watch does best.

When you upgrade to these new models, expect your accessories to fit better, work smoother, and unlock features that weren't possible before.

Share:

Apple introduces the powerful new iPad Pro with the M5 chip

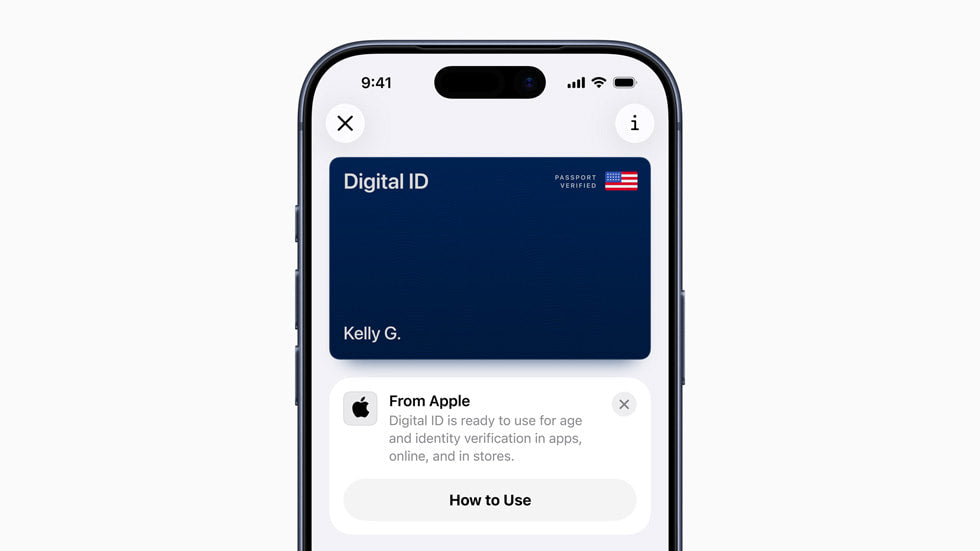

The end of physical IDs? Apple Wallet's digital ID feature changes everything